Impedance controlling Capacity

Impedance, generally measured in Ohms is a characteristic of the circuit that has to be taken care of during design of the pcb. Resistance and reactance of an electrical circuit have a major impact on functionality, as certain processes must be completed before others to ensure proper operation. This chain of command disrupts a system and leads to a complete failure when these actions aren’t performed as planned. Printed circuit boards with impedance requirements will nullify the changes in voltage occurring and lead to an appliance or gadget that operates as expected.

The use of differential impedance PCB components provide the control needed for a range of products. We can recommend software programs designed to detect resistance and reactance flow, providing you with the specs you require. Cyzon will use this data to create custom PCBs. The resulting circuitry is cost effective and provides heightened reliability.

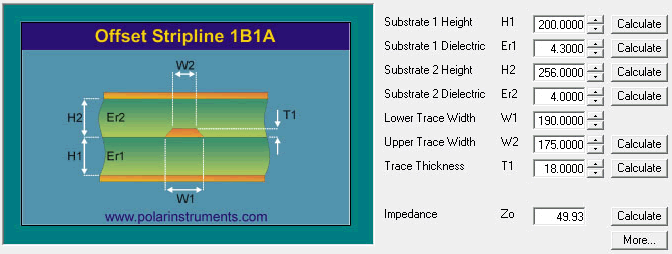

The pcb design factor’s affecting impedance are: Trace width, copper thickness, dielectric thickness, dielectric constant.

1. We use Polar software to design the stackup of the pcb as the impedance requirements .

2. According to the result , we adjust the trace width , trace space or dielectric thickness .

3. When boards finished , we test the impedance to control as +/- 10% tolerance .

Send Email

Send Email 15889340690

15889340690