Shengyi Releases Ultra-Low Loss PCB Laminate

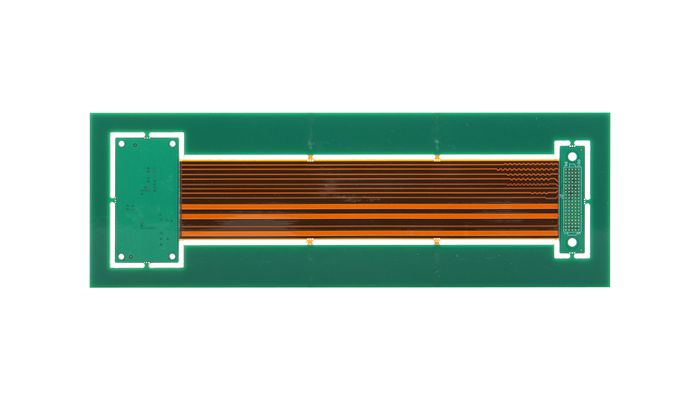

Shengyi Technology Co., Ltd. (SYTECH) has developed a PTFE based ultra-low Insertion loss controlled dielectric printed circuit board laminate called mmWave77. The laminate material exhibits excellent electrical properties with stability over frequency, temperature and environmental changes that provides for long term reliability.

The SYTECH mmWave77 Laminate Material features:

Process Dk is 3.0 +/-0.04, Df 0.0010 @10GHz (stripline method)- mmWave77’s Design Dk is 3.06 and Insertion Loss is - 1.29 dB/in @77 GHz, based on 0.127mm (5mil) dielectric thickness, 12mil line width and H/H foil. mmWave77 electrical properties have been designed to align with the industry leading laminate of choice for 77 GHz ADAS radars.

Dielectric constant (Dk) is stable between -40? and +150? at up to V-band frequency. Temperature Coefficient of Dk (TcDk) is between -12 and -20 ppm/? (-40?~+150?).

Dielectric thickness tolerance is 0.127 +/- 0.006 mm (5mil +/- 5%).

Ceramic filled PTFE composition provides industry’s lowest transmission loss, resulting in the highest transmission efficiency for mission critical automotive safety radars.

The construction of mmWave77 non-reinforced PTFE with ceramic fillers exhibits homogeneous in uniformity in all three directions.

Low moisture absorption and environmentally stable.

Process friendly. mmWave77 is constructed to minimize process chemical penetration and is laser ablation compatible. It is suitable to build mixed dielectrics boards.

High thermal reliability passing strict solder float (288?, 6X), thermal cycling tests (-65? to +125?, 500 cycles) and IST (23? to 150?, 1000 cycles).

SYTECH mmWave77 is designed, constructed and manufactured to meet the demanding electrical performance as well as reliability and safety requirements of 77GHz automotive radars. This new generation of product is an ideal cost-effective replacement to the mainstream PTFE laminate of choice of ADAS radar designs. SYTECH material provides an exceptional overall value proposition relative to overall cost with an emphasis on quality, product consistency and product availability.

SYTECH possess in house advanced test capability platform to measure the electrical performance of controlled dielectric materials up to 110 GHz for both R&D and quality consistency lot to lot material monitoring. With greater than 16 years of experience dedicated in supplying electronic materials to the automotive industry SYTECH management is committed to state-of-the-art process, quality control and overall continuous improvement systems and concepts. SYTECH Corporation qualified for ISO/TS16949 (2004) and recently updated to IATF 16949 (2018).

Send Email

Send Email 15889340690

15889340690