Europes Economic Recovery & Future Depends on Electronics Manufacturing Industry

A new IPC study, Digital Directions, Greener Connections, finds the electronics manufacturing industry has largely withstood the negative effects of the COVID pandemic and is poised to help drive Europe’s economic recovery and resilience, especially if anticipated government decisions take a supportive approach.

The study highlights the importance of electronic systems, especially those embedded into end user-electronics from industrial robots to an Airbus A350 to 5G infrastructures, as a main driver of global GDP growth. It forecasts the industry's global compound annual growth rate at 3.7 percent per year for the 2018-2023 period while the World Bank forecasts overall global growth of 1.8 percent over the same period. As Europe transitions to a digital and green economy, its electronics manufacturers are poised for robust growth following many years of declining global market share.

The study, conducted by Decision Etudes & Conseil and commissioned by IPC, a global electronics manufacturing association, includes a detailed analysis of Europe's strengths and challenges in this critically important sector and government policy recommendations to boost the resilience and competitiveness of the industry in Europe.

"Although the pandemic shattered many industries, the data shows the electronics manufacturing industry will be a key sector responsible for driving European's economic recovery and meeting future market needs” said Alison James, IPC Senior Director of European Government Relations. "For critical mission sectors – transportation, industrial equipment, aerospace and defense, IT and telecommunications, and healthcare – to rebound from the pandemic and build towards the future they'll need government policies that strengthen the resiliency of the electronics manufacturing industry as a whole."

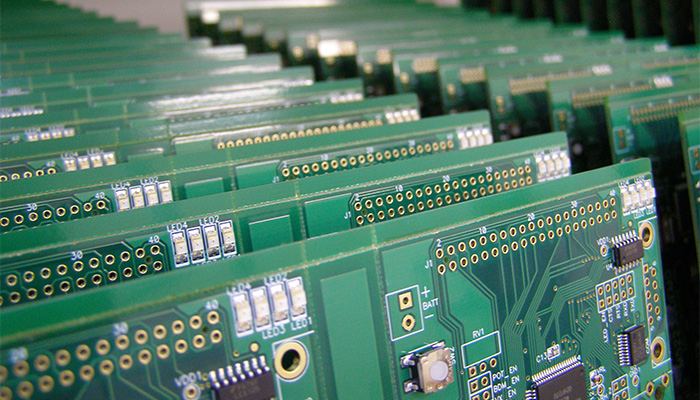

The study highlights the electronics manufacturing industry accounted for €301 billion in production value in 2019 and directly impacted €3.8 trillion in European GDP. It reveals that today, however, the EU accounts for only around 5 percent of the overall global production of printed circuit boards (PCBs) and 10 percent of electronics manufacturing services (EMS), key elements of the electronics manufacturing ecosystem.

The study comes as crucial decisions are being made at the European Commission (EC), which is releasing a revised industrial policy strategy later this month; and in national capitals, where COVID-recovery plans are being developed for potential financial support from the EC. Momentum also is building to invest in next-generation processors and semiconductor technologies. The European Union's Recovery and Resilience Facility will make €672.5 billion in loans and grants available to support reforms and investments undertaken by Member States, with 20 percent of the funding dedicated to foster the digital transition. Member States are set to submit their plans for spending by the end of the month.

"This report makes a powerful argument for a holistic policy approach to the electronics manufacturing industry as the EU seeks to revive economic growth and further its digital and green transitions," said James. "There is now a series of opportunities to align policies, partnerships and investments to achieve these ends."

To support the electronics manufacturing industry, the report offers a series of recommendations including:

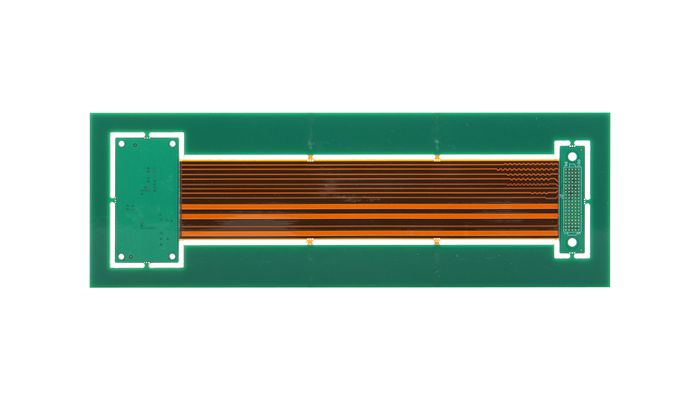

Recognize electronics manufacturing as a strategically important industry and invest in neglected parts of the value chain. While semiconductors and microelectronics' strategic importance is generally well recognised, the report notes that progress also depends on investments in the manufacturing of PCBs and electronic board assemblies. When governments invest in microelectronics, there should be gap analyses to assess corresponding needs in PCB fabrication and assembly. These sectors also should benefit from dedicated funding initiatives, such as the Recovery and Resiliency Funds.

Support European manufacturers in their transition to factories of the future, strengthening the industry and promoting digital transformation. As most European PCB and EMS companies are small and medium-sized enterprises, they particularly need support for investments in R&D, equipment upgrades, and workforce training to create the more connected, efficient factories of the future.

Enhance vocational training and lifelong training. The European Microelectronics Pact for Skills, launched in 2020, aims for an overall public and private investment of €2 billion to upskill and reskill more than 250,000 workers and students by 2025. Here again, the report recommends including PCB makers and assemblers in those programs, and it suggests that Member States' recovery plans should include projects dedicated to upskilling workforce in Industry 4.0 tools and technologies, paying special attention to small and medium-sized enterprises.

Focus on Europe's leadership in embedded electronics – which account for 85 percent of its electronics output – to help achieve successful green and digital transitions. Supporting these end-user sectors will help drive overall growth and bring about cleaner, more connected, autonomous vehicles and more intelligent, secure, and efficient homes, factories, and healthcare systems.

In defining the European concept of "open strategic autonomy," strike a careful balance between support for regionalized production and a flexible global supply chain. This includes working with like-minded partners at the multilateral and bilateral levels to enforce trade rules and avoid creating new trade barriers.

Send Email

Send Email 15889340690

15889340690