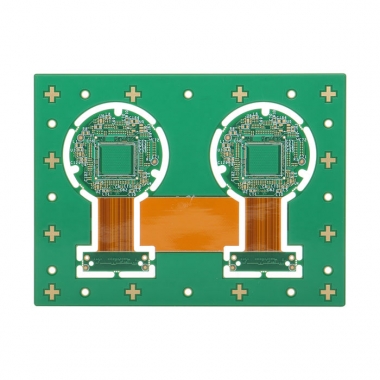

| Name: | 12 layers rigid-flexible PCB |

|---|---|

| Board thickness: | 2.0mm |

| Copper thickness: | 1OZ |

| Minimum line width/space: | 4/4 mil |

| Minimum drilled hole diameter: | 0.25MM |

| Surface finish: | ENIG |

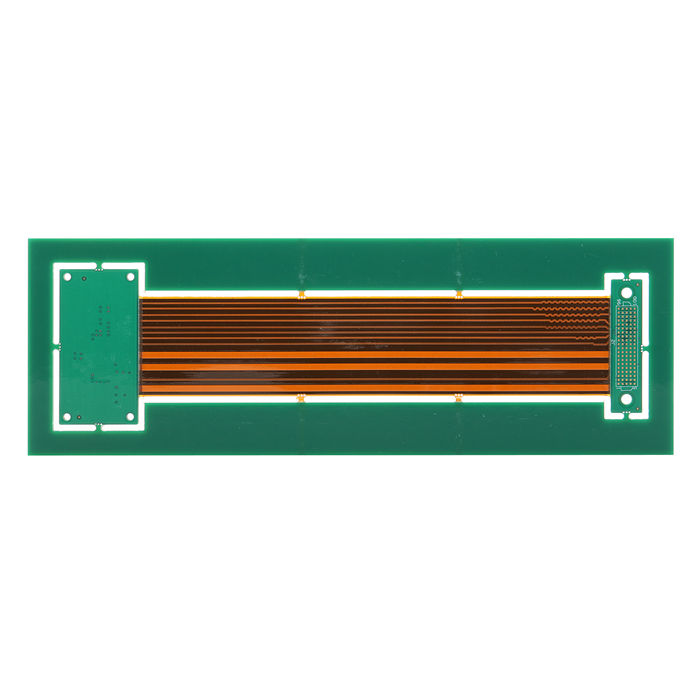

| Special process: | mix lamination with 2 layers FPC |

| Inquiry |

Product Description

12 layers rigid-flexible PCB for telecom products .

The rigid-flex printed circuit board gives you the best of both worlds. A rigid-flex PCB combines the flexibility of flex circuits with the durability

of a rigid PCB. A flex-printed circuit board has only flexible materials, usually polyimide or polyester-based. They can be single-layer, double-

layer or multilayer boards. A rigid flex PCB has both flexible and rigid materials, with flexible layers sandwiched in between rigid layers with

conductors and plated through holes that connect them to the other layers.

Flexible circuit boards by themselves may not stand up to the wear of certain challenging applications, but standard rigid boards tend to be

heavy and take up a lot of space. Combining rigid boards with flexible circuits reduces weight and space, giving you a streamlined product you

can use in a wide variety of industrial situations.

Connection Reliability – Connecting rigid layers with flexible cables is the foundation for combination rigid flex circuits.

Lower Part Count – Compared to a traditional rigid board, combination rigid flex circuits require fewer parts and interconnections.

Flexible Design Options – At Flexible Circuit Technologies, we pride ourselves on taking on the most complex of design challenges. Rigid flex

circuits can be designed to meet highly complex and unimaginable configurations while utilizing a rigid substrate. Rigid flex circuit designs could

entail any of the following:

Highly complex configurations

Controlled Impedance

Three to eight-layer combinations

Reduced interconnections

High Density Applications – More often than not, the rigid component of a rigid flex circuit is utilized for high density device population. In

addition, flexible circuits allow for minutely narrow lines giving way to high density device population. Denser device populations and lighter

conductors can be designed into a product, freeing space for additional product features.

Package Size and Weight Reduction – Multiple systems in rigid boards create more weight and utilize more space. Combining rigid boards with

flexible circuits allows for a more streamlined design thus reducing package size and weight.

Related Product

Send Email

Send Email 15889340690

15889340690