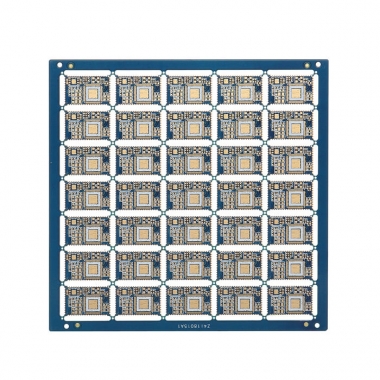

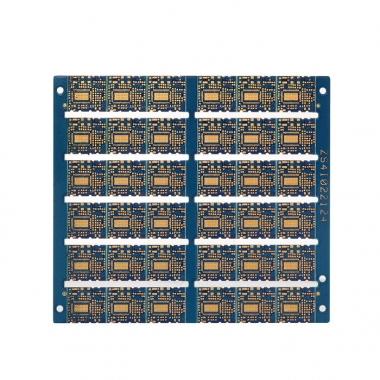

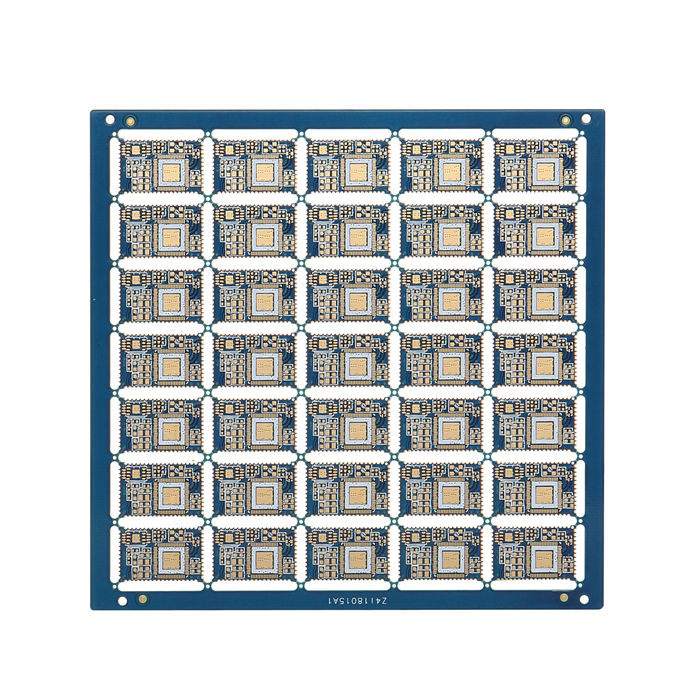

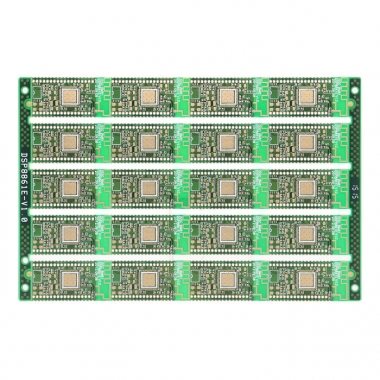

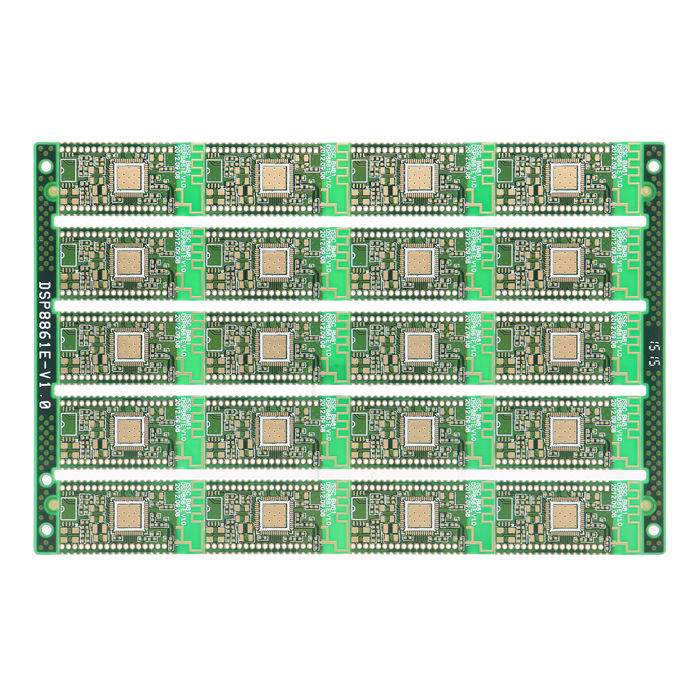

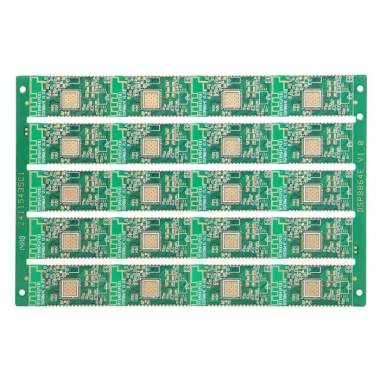

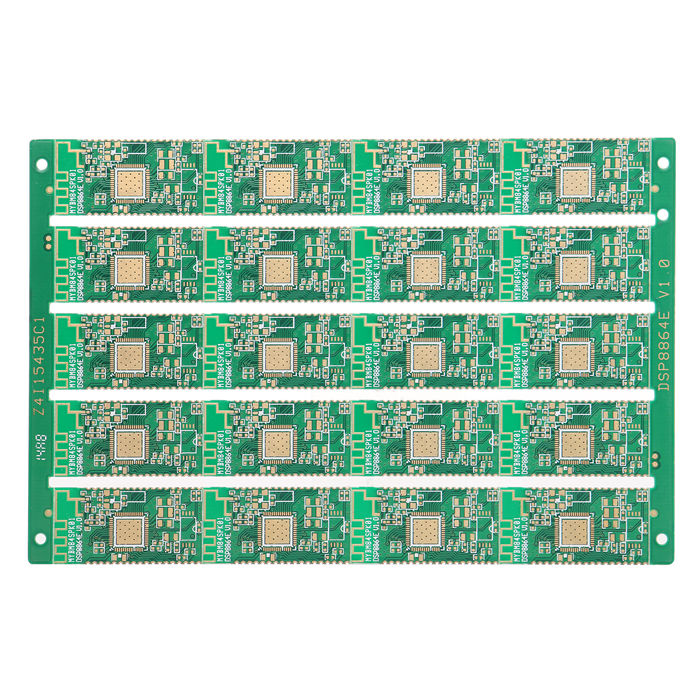

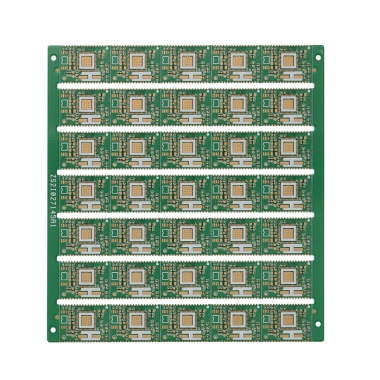

| Name: | 2 layers PCB with half holes plated |

|---|---|

| Board thickness: | 0.8MM |

| Copper thickness: | 1OZ |

| Minimum line width/space: | 6/6 mil |

| Minimum drilled hole diameter: | 0.35MM |

| Surface finish: | ENIG |

| Special process: | impedance control , half holes plated |

| Inquiry |

Product Description

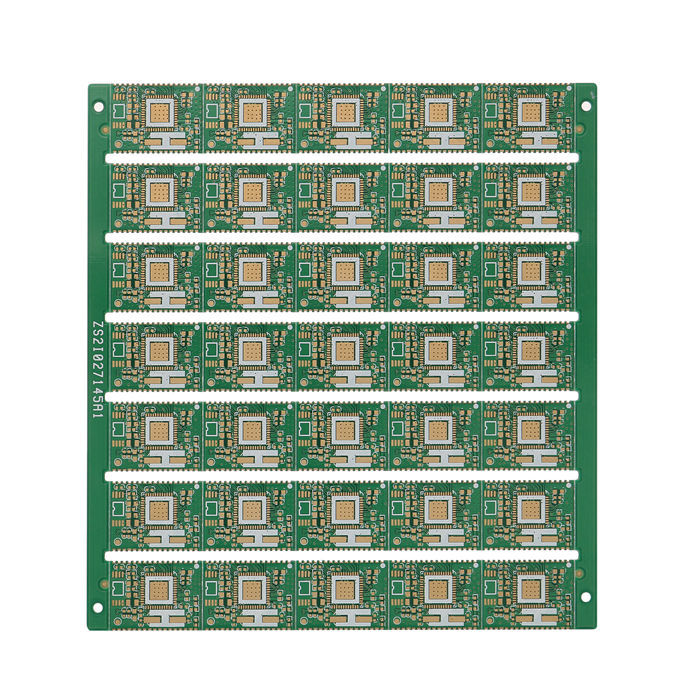

2 layers PCB with half holes plated

Plated half-holes or castellated holes are plated half holes with half on the edges of the board. They are commonly used for breakout boards or small modules. You may have seen them on some Wi-Fi modules which are then soldered onto a larger PCB similar to the way in which ICs are mounted. Castellated holes are not available for single layer boards.

How are they manufactured?

Firstly, whole plated through holes are made as usual on the edge of the boards. A milling tool is then used to cut the holes, along with the copper, in half. Since copper is much harder to mill and will likely cause the bit to break, heavy duty milling bits are used at a higher speed. This results in a smoother finish. Each half hole is then inspected in a dedicated station and deburred if necessary.

Send Email

Send Email 15889340690

15889340690