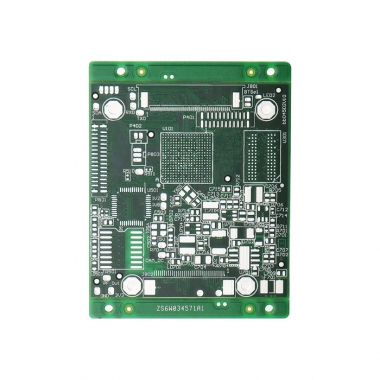

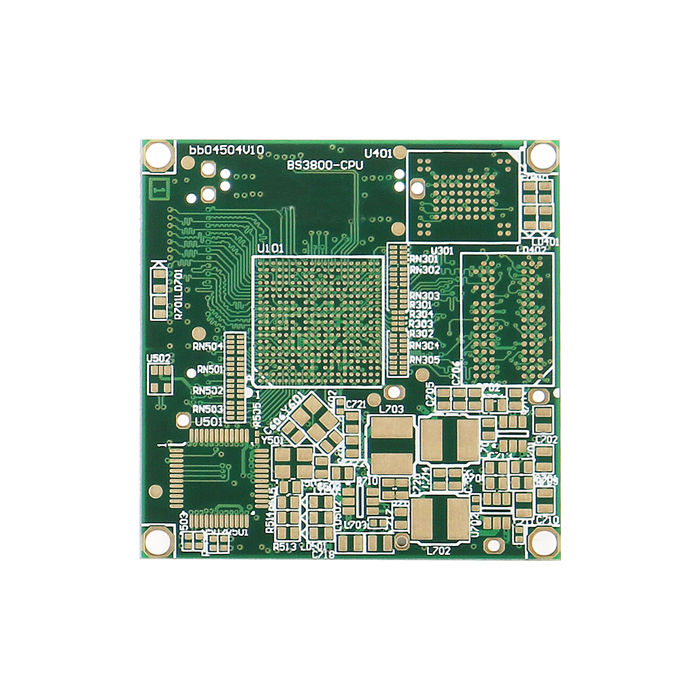

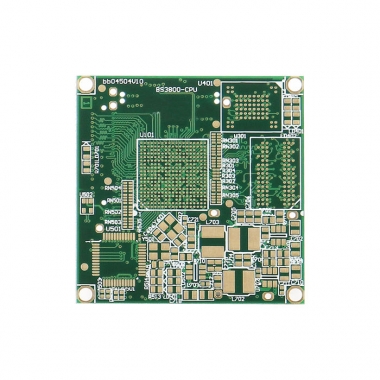

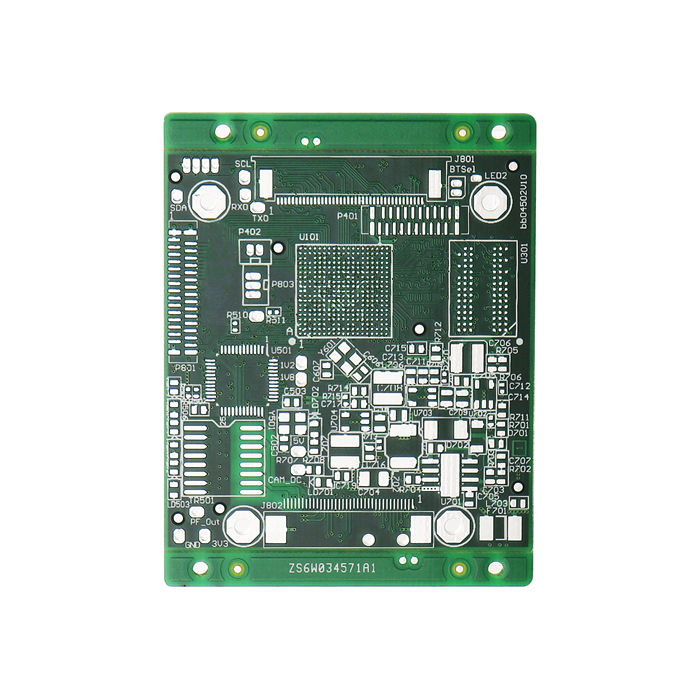

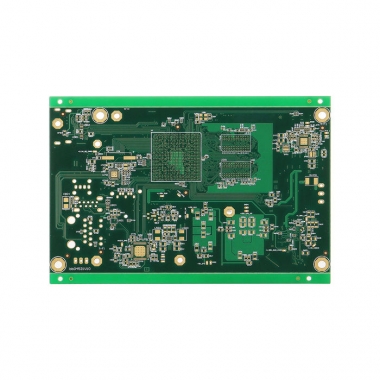

| Name: | 8 layers impedance pcb |

|---|---|

| Board thickness: | 1.60mm |

| Copper thickness: | 0.5OZ |

| Minimum line width/space: | 3/3 mil |

| Minimum drilled hole diameter: | 0.25MM |

| Surface finish: | ENIG |

| Special process: | impedance control |

| Inquiry |

Product Description

8 layers impedance pcb

HDI stands for High-Density Interconnector. Therefore, HDI PCB is described as a printed circuit board that has a higher electrical connections density per unit area when compared with a standard board. They come with better spaces and lines, small capture pads, small vias, and high electrical connections pad density compared to the traditional PCBs. HDI PCBs benefit from laser drilling engineering and require little room.

It has made it possible for the circuit boards to be as compact as you may want. Regardless of this decline, the performance of your product would remain uncompromised. Differently put, you can call every PCB with about one hundred twenty to sixty pins that are one square inch as

an HDI PCB.

HDI PCB Application

Healthcare

HDI PCBs have a substantial impact on the medical sector. Hospitals use medical equipment usually composed of HDI PCB. For example, tiny devices such as imaging equipment, implants, and lab.

Automotives

The small HDI PCBs mainly draw the automotive industry because it creates additional space within the vehicle.

Tablets and Smartphone

The smartphone, tablet, or laptop you are currently using to read this article is HDI PCB. PCB manufacturers are using HDI PCBs for developing portable and lightweight electronic products.

Wearable Technology

HDI PCBs also support products such as VR headsets, apple watch, and other wearable tech devices.

Aerospace and Military

The military is also implementing HDI PCBs for their defensive hardware and communication strategies. Further, HDI PCBs are compliant with dangerous and challenging environments that allow them to be ideal for military and aerospace industries.

The Future of HDI PCB

HDI PCBs are taking technologies to the next level. It is playing an essential part in electronic devices production. With its advances, this technology meets the most significant challenges. HDI PCB is a technology for you. Especially if you are looking for technology that allows you to work anywhere, anytime efficiently. Therefore, the potential of this technology is very promising as demand continues to increase and not to decline.

Send Email

Send Email 15889340690

15889340690