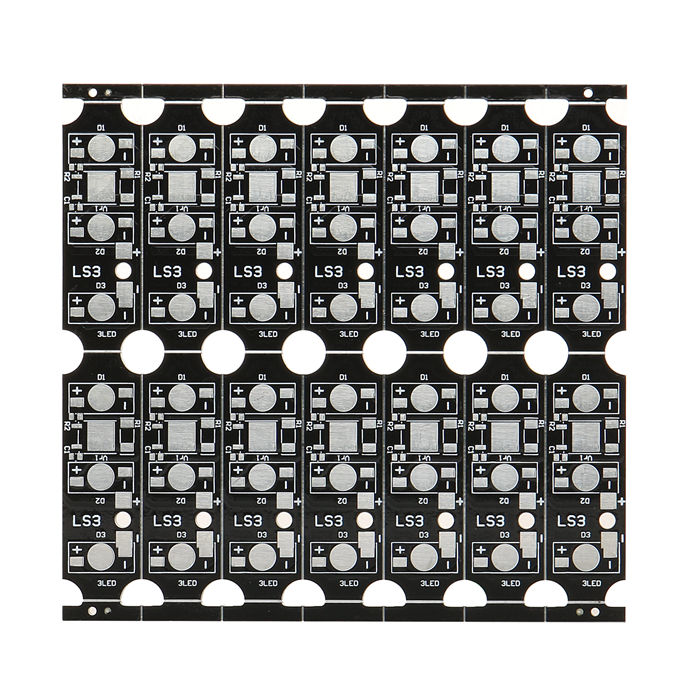

| Name: | Single sided aluminum PCB |

|---|---|

| Board thickness: | 2.60MM |

| Copper thickness: | 2OZ |

| Minimum line width/space: | 12/12mils |

| Minimum drilled hole diameter: | 3.5MM |

| Surface finish: | HASL Pb free |

| Special process: | black soldermask , aluminum |

| Inquiry |

Product Description

Single sided aluminum PCB for LED products

Aluminum core PCBs is a metal-based, copper-clad laminate that delivers high performance, including excellent thermal conductivity and electrical insulation.

Metal core PCBs have a unique set of advantages compared to other base materials:

Less expensive.

Aluminum is indigenous to a variety of climates, so it’s easy to mine and refine. That makes it significantly less expensive to mine and refine than other metals. By extension, the manufacturing costs associated with products using aluminum PCBs are also less expensive. Aluminum PCBs are also a less expensive alternative to heat sinks.

Friendly to the environment.

Aluminum is a non-toxic, recyclable metal. From the manufacturer through to the end consumer, using aluminum in PBCs contributes to a healthy planet.

Better heat transfer.

High temperatures are the cause of heavy damage to electronics. Aluminum conducts and transfers heat away from critical parts to minimize damage to the printed circuit board.

Very durable.

Aluminum is stronger and more durable than base materials like ceramic and fiberglass. It is very sturdy, and reduces accidental breakages that can occur throughout the manufacturing process, and during handling and everyday use.

Aluminum PCB Applications

Aluminum back PCBs are ideal for situations when thermal heat dissipation requirements very high. PCBs clad with aluminum are more effective at directing thermal energy away from printed circuit board components therefore provide better temperature management for PCB designs. Aluminum-backed designs can be as much as ten times more efficient than fiberglass-backed designs when it comes to removing thermal energy from circuit board components. The much higher thermal dissipation rate allows higher power and higher density designs to be implemented.

Aluminum-backed PCBs are used more than ever for applications of high power/high thermal heat dissipation. Although they were originally designed for high power switching supply applications, aluminum-backed printed circuit boards have gained popularity in LED applications, including traffic lights, automotive lighting and general lighting.

Send Email

Send Email 15889340690

15889340690